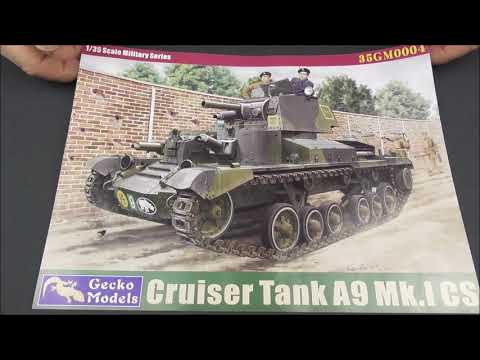

Cruiser Tank A9 Mk.I

Gecko Models | N. 35GM0003 | 1:35

I fatti

- Marca:

- Gecko Models

- Titolo:

- Cruiser Tank A9 Mk.I

- Numero:

- 35GM0003

- Scala:

- 1:35

- Digita:

- Kit completo

- Messo in commercio:

- 2018 Nuovo stampo

- Codice a barre:

- 4892667350033 (EAN)

- Argomento:

- A9 Cruiser » Carri armati (Veicoli)

- Listed on:

Contenuto della confezione

Plastic sprue, Fotoincisioni, Asta, Corda, Foglio di decals (applicabile con acqua)

Dimensioni:

410x245x90 mm

(16.1x9.6x3.5 inch)

Peso:

930 g (2.05 lbs)

Genealogia

Gecko Models

Istruzioni

Scaricare 9834Kb (.pdf)

Mercato

No partner shops available

Recensioni in-box

Revisioni esterne

Revisione Modellbau-Koenig

Revisione Modellbau-Koenig database di modellazione dei treni | gestore della mia scorta

database di modellazione dei treni | gestore della mia scorta